German study on infection control on cruise ships and cargo ships: Thermal decontamination completely eliminates the coronavirus Sars-CoV2

As reported by a German news presenter, the crew of a cargo ship was quarantined in the German city of Hamburg because several of the 23 crew members were infected with the coronavirus. The ship, which transports goods between Hamburg and West Africa, has now left the port again after a quarantine period of around three weeks. This incident is not an isolated one. Already in February, the cruise ship “Diamond Princess” together with its 2,666 passengers and 1,045 crew members was quarantined, as there were also corona outbreaks among the passengers. The outcome after more than 2-weeks of quarantine was alarming: 705 infected, six dead. Coronavirus had therefore continued to spread on the ship despite quarantine and appropriate disease control measures.

Coronavirus still detectable 17 days after end of quarantine

To trace the causes of this huge outbreak, scientists from the US Centers for Disease Control and Prevention (CDC) examined the cruise ship. Even 17 days after the evacuation of the ship – but before the subsequent disinfection – they found residues of coronavirus RNA in the cabins of infected passengers. The results of the study show that coronavirus can survive on surfaces much longer than previously assumed. Door handles, elevator controls, but also cutlery boxes in the canteen and table surfaces are possible sources for a smear infection with the coronavirus. Laboratory tests of another scientific study reported in the “New England Journal of Medicine” confirm this finding. According to this, the SARS-CoV-2 virus can remain on cardboard or paperboard for up to 24 hours, and on plastic as much as 72 hours.

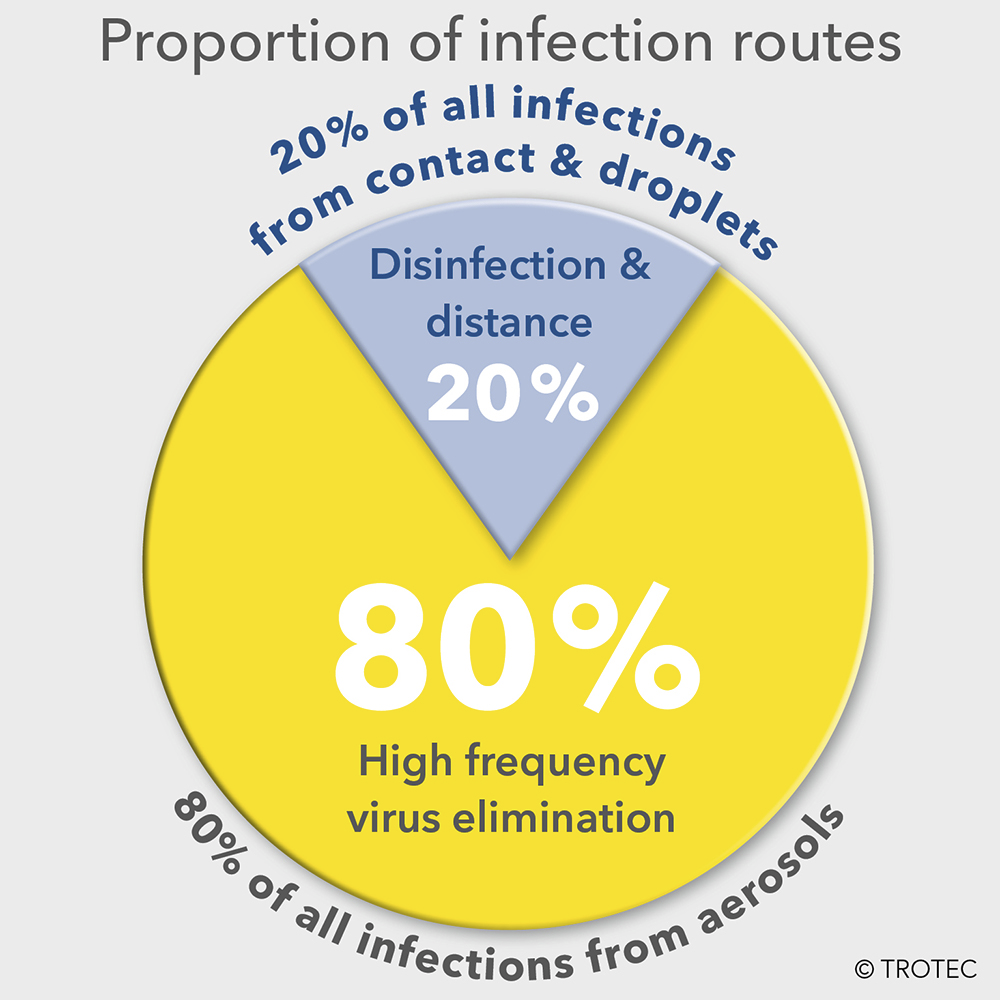

All transmission paths must be taken into account when protecting against infection

It is therefore imperative to take sufficient account of “all” modes of transmission in infection control and not only to concentrate on droplet infection in hygiene measures, as has long been the case.

The solution from Heinsberg promises a remedy: Thermal disinfection with an HEPA air purifier

Combined protection against contaminated surfaces as well as infectious aerosols in indoor air has now been developed in Heinsberg and tested in the course of various studies. The novel thermal disinfector TES 200 with HEPA virus filtering enables uncomplicated and complete surface disinfection of all surfaces in a room, especially on cargo and passenger ships. In addition, the mobile applicable device has an integrated high-frequency air purifier with special H14-HEPA filtering to filter infectious aerosols from indoor air – before they are inhaled unnoticed. Scientists and virologists are in agreement on further point. In addition to the droplet and smear infection, the coronavirus is also transmitted via inhaled indoor air. To be more precise, by so-called aerosols, which are a mixture of gas (usually air) and solid or liquid components, which in people who are unwell, contain viruses. These tiny floating particles are mainly released into the air when breathing and speaking. While the large droplets sink to the ground after only about 1.5 meters due to their weight (which informs the social distancing rule of 1.5 meters), aerosol particles can float in the air for several hours owing to their small size (about 0.3 – 0.4 µm). The situation is further aggravated by the fact that even more aerosol particles are produced in the lungs of infected persons and released via respiration.

Increased risk of infection on cruise ships

The decisive factor for the risk of infection with the coronavirus is the length of time for which viral aerosols remain in indoor air. This is because unlike outdoor air, where aerosol mixtures are diluted and blown away by the movement of clean fresh air, the aerosol concentration indoors remains continuously high. This is the case in the various restaurants on board or example, or also in the entertainment areas containing many spectators. The longer the time and the higher the amount of aerosol particles floating around in the air, the faster they enter the body via the respiratory tract and lead to lung infection. Even in only one cubic centimetre of air about 50,000 particles such as dust, pollen as well as bacteria and viruses can be found. And as each additional person in the room breathes, the aerosol concentration in the room increases by thousands of particles per minute.

Sounds a little medical? Well, it is! In hospitals and medical practices, thermal disinfection and high-frequency air purifiers have long been regarded as proven protection against infection. Medical equipment is kept sterile and germ-free by means of thermal disinfection. Even for the decontamination of hygiene-sensitive respiratory masks, the process is approved for the multiple use of disposable masks in medical applications. And what disinfects the syringes at the doctor’s and keeps operating theatres in hospitals free of viruses and germs now also reliably removes viruses and germs as a mobile solution from all surfaces in the room and, if necessary, even from the indoor air.

No additional effort: heat treatment replaces disinfection by wiping

In simplified terms, the novel thermal disinfector TES 200 primarily treats the indoor air and generates different temperature phases in the range of 60 °C – 70 °C during thermal treatment according to a complex heating system. This heating process leads to the inactivation of any SARS-CoV-2 viruses that may be present on door handles, tables, objects and all other surfaces. Time- and personnel-intensive disinfection by wiping is not necessary.

In practice, this is easy to do: The mobile applicable device heats the room temperature fully automatically according to a preset program, so that all viruses and bacteria present on surfaces and objects are inactivated within a few hours. If required, thermal disinfection can also be carried out overnight.

The advantages of thermal disinfection at a glance:

- Whole rooms are free of germs and viruses after only a few hours

- Seamless disinfection of all surfaces – without personnel deployment

- An additional wipe disinfection of the surfaces is not necessary

The coronavirus poses an enormous challenge, especially for hygiene measures on cruise ships. Many people share dining rooms, buffets, numerous fitness facilities and other on-board facilities. The first shipping companies are already starting cruises again, but now with distance markings and microbial samples that are evaluated directly on board. The combined surface and air purifier TES 200 supplements these protective measures.

Because: Once corona restrictions have been lifted, it will not be a question of simply going back to the normal routine. The health protection of employees and passengers must also be taken into account in the future. This is made possible by the TES 200.

Combined surface disinfection and HEPA virus filtering

The TES 200 was designed, manufactured and tested in various studies in Heinsberg – immediately after the first cases of corona infection in Germany became known. The primary objective of the Trotec engineers was to develop a device that was as multifunctional as possible to combat the new type of corona virus. In combination with a- HEPA virus filter manufactured exclusively by Trotec, the TES 200 is not only suitable for thermal disinfection but also for effectively keeping the room and breathing air clean.

The air cleaning concept of the TES 200 is based on two foundations:

- Firstly, the aerosol concentration in the indoor air is continuously and effectively diluted with virus-filtered HEPA clean air. For this purpose, the air purifier has a clean air capacity that is unmatched in mobile devices and allows for an air exchange rate of up to 20 times per hour.

- Furthermore, airborne viruses and bacteria are first separated in a new type of heat-resistant HEPA particulate filter and then killed cyclically by thermal decontamination. This special protection class 14 filter, developed exclusively by Trotec, features a separation efficiency of 99.995 percent for particle sizes of 0.1 to 0.2 µm. Thanks to these properties, H14 high-performance filters are even used in operating theatres and in comparably hygiene-sensitive areas to produce clean air.

In simple terms, the TES 200 transfers the air situation outdoors to the situation in closed rooms and supplements this with highly efficient virus filtering and inactivation.

What sounds very technical in theory proves to be extremely uncomplicated in practice. The draught-free intake of the polluted room air takes place close to the floor and the virus-free clean air is discharged vertically upwards into the room. Even large-surface clean air areas can be free of dangerous aerosol pollution thanks to mobile design and the use of several TES 200 air purifiers.

There is no better protection for employees and passengers. Optimally virus and germ-free surfaces as well as permanently filtered indoor air, to protect against the inhalation of infectious viruses.

The thermal disinfector TES 200 is available right away starting at the basic price of €4,754.05 in the Trotec online shop.

The Trotec team of experts will be happy to answer any questions you may have:

Trotec GmbH, Mr Jochem Weingartz

Telephone: +49 2452 962-137, jochem.weingartz@trotec.com