Practical applications are on the agenda in today’s third and last part of our small jigsaw seminar. We will focus on how jigsaws are correctly operated and applied: from the change of the saw blade, to setting the pendulum stroke and the varying saw techniques of a straight, round and a slanted cut. To conclude, we will take another look at the necessary care after using the tool.

How to change the saw blade

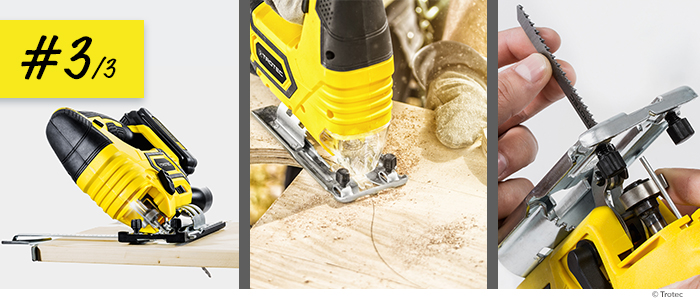

After choosing the correct saw blade, insert it in the jigsaw. That’s very simple to do, as practically all machines today provide a quick clamp device that makes changing the blade significantly easier and avoids inappropriate blades being used for the component. This quick clamp device is either a lever that is pushed downward or a slider that is slid to the side. Inserting the saw blade in the socket is sufficient for its use – a clicks signals that the seal is engaged.

How the pendulum stroke is adjusted

Next you should check the jigsaw’s pendulum stroke setting. It is sensible, depending on the material and cut required, to engage or disengage the pendulum stroke. In principle, the pendulum stroke blades only provide a decisive advantage for saws of hard and thick woods. Thus, material is sawed through significantly faster and more easily, since the saw blades are better utilized and the friction on the saw tooth is reduced – among other advantages, this results in the saw blade having a longer lifespan. The disadvantage of an engaged pendulum stroke is the somewhat rougher cross section. On the other hand, if an especially clean cut is of importance, the pendulum stroke should be reduced and if necessary switched off completely. The same holds true in the curve cut, especially for tight radii. The pendulum stroke setting is in this case quite disadvantageous and should be switched off. You should always saw metal without a pendulum stroke, since the shavings are substantially smaller and therefore can easily discharge.

The straight cut with the jigsaw

Before the first cut you should always check again to see whether the saw blade is appropriate for the component and also whether the required cutting depth is reached. For example, for soft woods of a lower thickness, you should choose a 75 mm long blade with a fine serration and normal width. In this case, the pendulum stroke should be switched on – and very importantly – the component fastened with screw clamps.

Now you can begin to cut into the component from the edge inwardly or to trim it to the required length. Components are actually always cut from the edge inwardly. On the other hand, if you would like to saw a section in the component, a hole should be drilled at a distance of 5 mm inside of the planned cut-out with a 8-10 mm drill, the saw blade inserted and cutting then started from this point. There are even saw blades appropriate for the so-called plunge cut. This, however, requires considerable practice and you should first have an experienced handyman demonstrate.

The round cut with the jigsaw

Two process steps distinguish the round cut from the straight cut: Deactivate the pendulum stroke and replace the saw blade with one that is thin and appropriate for curve cuts. For tight curves, work with so-called relief cuts that are carried out at about 10 mm from one another: While cutting the curve, the saw blade is relieved through the immediate disappearance of the section and the cross section becomes cleaner. If you would like to round off the edges, it is recommended to cut along the length of the grain, as the least amount of wood shavings are generated.

The slanted cut with the jigsaw

In order to carry out an angled cut with the jigsaw, you need to adjust the foot plate of the machine with the help of a quick-release fastener or a screwdriver. Once the angle is adjusted, it is imperative the length of the saw blade is checked – the larger the angle is, the longer the saw blade must be, in order for it to completely cut through the component. Now you can complete this cut both for straight and curved cuts.

Cleaning the jigsaw

With today’s modern jigsaws, there is little to do since they are ordinarily maintenance-free. However, cleaning has never damaged a tool and a clean and neat tool is after all the mark of a professional. First, you should disconnect the jigsaw from the power supply. Then remove the sawdust and other impurities, especially near the saw blades and pendulum wheel. An old toothbrush does the job here. Then a few drops of oil on the pendulum stroke and the cleaning is finished.

Jigsaws with pendulum stroke from the PJSS Series – in Trotec brand quality

As a passionate DIY enthusiast, you should not miss this opportunity: Take a look now at our wide ranging offers of PJSS jigsaws with pendulum stroke. Either with battery, cable and bow handle or with cable and knob handle: Every model is an outstanding power tool from Trotec with an unbeatable price-performance ratio – now in the Trotec shop!