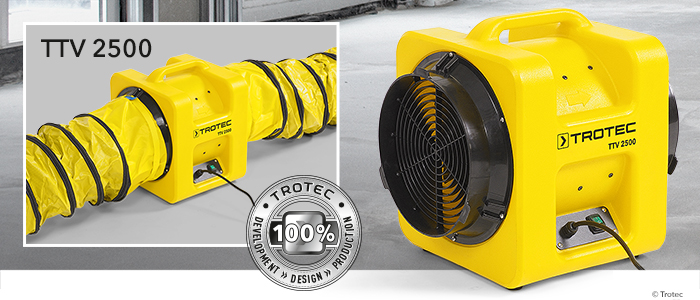

Fresh air for your construction site! With its high-performance fan, the TTV 2500 conveying fan can variably transport fresh air over long distances into adjacent storeys or shafts and exhaust polluted air over equally long distances. The robust yet light-weight conveying fan therefore possesses the optimal requirements for the necessary air exchange rates during the ventilation of channel construction works or welding.

The TTV 2500 conveying fan’s distinctive German industrial design with built-in carrying handle, shock-protected switch and stackable polyethylene housing make it clear from the moment you see it, that this device is a true professional. At the same time, the axial fan, with its high-performance, encapsulated fan, proves itself to be an economical solution for quick and easy ventilation tasks. It conveys a maximum discharged air volume of 2,200 m³/h, at an air pressure of up to 300 Pa.

This is how it works

The TTV 2500 axial fan is equipped with connections on both sides so that a hose of up to 38 metres long can be flexibly attached to the blow-out or suction sides of the fan. This allows, on the one hand, the combined use of an optionally available dust bag on the blow-out side and a similarly connected air hose on the suction side. In addition, the TTV 2500 is the ideal transport fan for far-off connected mobile air conditioning and heating applications.

The conveyor fan is also ideally suited to support cooling or heating units. To assist the cooling or heating units, the device is installed between the ends of two air transport hoses and so extends the conveying distances of hot or cold air even for very long hose routes. Moreover, thanks to their practice-optimised industry-design, TTV 2500 fans can be stacked on top of each other. This allows for even more flexible usage and is also space-saving when transporting or storing the fans.

Four of the many advantages that I particularly like:

- its development, design and manufacture are 100 % Trotec

- its double-sided hose connection nozzle on the discharge and suction side

- its sturdy polyethylene housing

- its space-saving stackability for storage and transport